We all know that supply chains are badly affected by the coronavirus induced crisis. But what is it about supply chains that we can learn from firms that seem to have weathered it and are prospering.

1.Just in Time works till it suddenly doesn’t

2.Safety stock and building up of reserves is important.

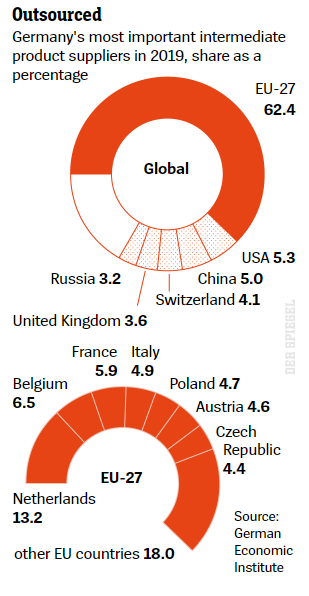

3.Account for the risk that single source and faraway suppliers pose.

Now dealing with all of the above means higher costs but also higher automation.

But what is the payoff?

Apparently Huge.

One can compare it to having an out of the market put which pays off spectacularly during times of crisis allowing you to bulldoze your competitor similar to getting high returns and thereby having more cash to invest at a time when everything is dirt cheap.

At agricultural machine manufacturer Grimme, production has continued at all its factories throughout the entire coronavirus shutdown.

Grimme has consistently refused to adhere to modern-day management principles, such as the idea that large industrial manufacturers must produce globally and outsource services to remain as flexible and efficient as possible. Damme has frequently examined whether such an approach would work for the company, but has always chosen to go another direction.

The company, if you will, is more old school, preferring to produce as much as it can at home, particularly critical parts like screens and reels. In-house production depth, a reference used by economists to measure how much a company makes itself, is around 85 percent. “We’ve always been laughed at because of it,” says Feld. Now, though, the erstwhile critics have become envious.

Whereas competitors such as Claas and Fendt have been forced to shut down their production lines, Grimme has become something of an avant-garde in the agricultural machinery industry and is indeed setting a trend for the economy as a whole.

A survey conducted by the association in mid-April found that 89 percent of companies have experienced clear hindrances to normal business operations. Supply chains, as has once again become apparent, are only as strong as their weakest link.

That, indeed, is the flip side of de-globalization: Bringing things home increases security but it raises costs and shrinks profit margins. Still, the price of independence can, perhaps, be minimized — using cheap labor and technology.

References